If you work with chemicals, it’s important that you invest in a ventilation system to keep toxic fumes out of the air. Fume hoods are necessary when working with gases, vapors, or dust that are hazardous in the event of exposure. They protect you from breathing in particles that can lodge in the lungs or enter the bloodstream.

Fume hoods also work to protect you from explosions and chemical spills. The safety glass is designed to “spider” instead of shattering in the event of an explosion, keeping those in the area safe from glass and chemicals when explosions occur. Most hoods also include spill-containment features, which can be especially important when working with exceptionally hazardous materials.

Whether you work on personal projects or in a lab, it’s important to determine what type of fume hood you should invest in.

1. Bench-top Fume Hood

A bench-top fume hood is a hood that sits on a work surface approximately 36” above the floor. Along with the hood, you will need a supporting base cabinet, a work surface, and an exhaust blower.

This type of fume hood will also need ductwork, which should be factored into your installation costs. Check out some bench-top fume hood and cabinet combinations here.

2. Floor-mounted Fume Hood

A floor-mounted fume hood, or a walk-in fume hood, is installed from the floor up instead of sitting on another surface.

It resembles a small room, allowing you to work inside the space. This is ideal when you may need to use oversized tools or equipment, such as drums, processing units, or robots while working with toxic chemicals. The large doors allow you to roll large apparatus or tables into the area as needed. These fume hoods can range in size depending on your needs but are generally the size of a small closet. Standard models range from 6 to 24 feet wide, 7 to 16 feet high, and 4 to 8 feet deep. However, these can be custom-made to fit your desired dimensions.

3. Double-faced Fume Hood

A double-faced fume hood is ideal for demonstrations. It has entrances on both sides and allows for 360-degree viewing. This type of fume hood can come as a typical bench-top or wall installation or as a portable unit. These are usually in classrooms or laboratories where teaching demonstrations are frequent.

Portable double-faced fume hoods are especially useful in shared learning environments, where the hood may need to be moved from one classroom to the next.

4. Portable Fume Hood

Portable fume hoods are also known as recirculating range hoods. They are ductless, which means that they operate off of a carbon filter system.

These hoods are cheaper, easier to install, mobile, and use less energy. The installation process requires no ductwork or wall penetration. They’re usually smaller or on wheels, so you’re able to move them to different areas of your lab. If energy usage is important, these are eco-friendly when compared to the energy usage of full-sized fume hoods.

While portable fume hoods may seem like an easier option, there are a few disadvantages to this model. The method by which toxins filter out can put workers at a higher risk of exposure. Filters also need regular maintenance.

Portable fume hoods are ideal if you work with less than 10 chemicals or small amounts of chemicals. The chemicals also need to be able to filter through the carbon.

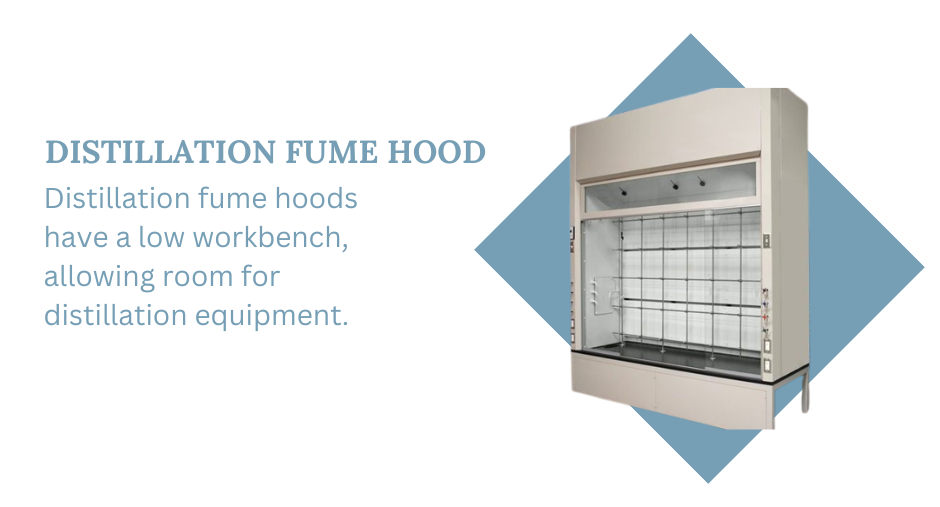

5. Distillation Fume Hood

A distillation fume hood is a specialized type of laboratory fume hood designed with a taller interior space. Compared to a standard fume hood, a distillation hood has much more internal height to fit large distillation equipment commonly found in chemical and pharmaceutical research, consumer product quality assurance testing, forensic testing, and the petroleum industry.

6. Perchloric Acid Fume Hood

Designed for handling perchloric acid, a perchloric acid fume hood has an inner water wash-down system and a built-in drain trough for detailed cleaning of the hood interior. The ductwork from perchloric acid hoods and exhaust systems should take the shortest path to the outside and should not mix with the other exhaust systems. Also, regular cleaning of the perchloric acid fume hood is vital to minimize the build-up of dust or material that can contain perchlorate salts.

7. Radioisotope Fume Hood

Specifically designed for handling radioactive materials, a radioisotope fume hood is built with stainless steel surfaces and coved seamless welded corners to forestall material build-up and stop contamination. Radioisotope hoods are usually made stronger than conventional fume hoods and the work surface is watertight.

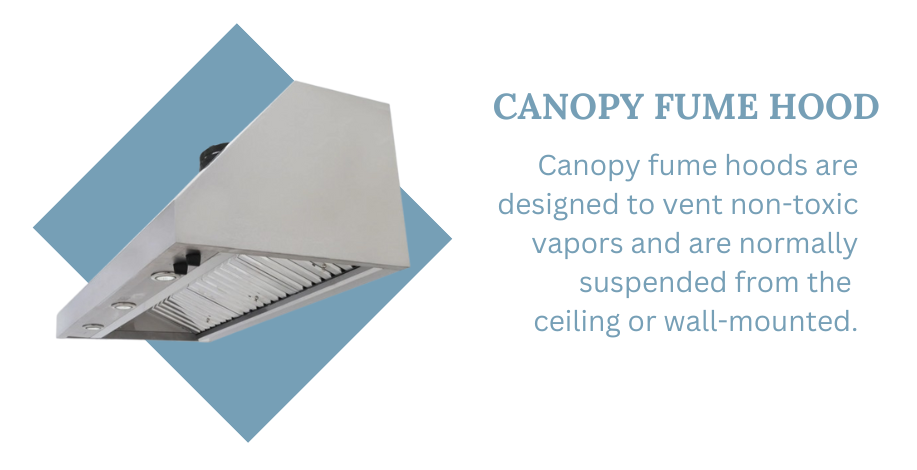

8. Canopy Fume Hood

Suspended or wall-mounted, a canopy fume hood is designed to vent non-toxic vapors like heat, steam, and odors from large equipment like ovens, autoclaves, or steam baths. Unlike a fume hood that is used for hazardous chemicals, a canopy hood captures contaminants in a wide area without requiring a physical barrier around the work surface.

9. Polypropylene Fume Hood

Designed primarily from polypropylene plastic, a polypropylene fume hood is a ventilation system that protects users from harmful fumes and vapors released by chemicals or corrosive acids. Due to polypropylene’s high resistance to chemical corrosion, it is ideal for applications where strong acids or other harsh chemicals are used. Polypropylene’s nonporous properties make the fume hood odor resistant allowing them to perform well in food processing plants and cleanroom environments.

Next Steps

The right type of fume hood will depend on many different factors; such as how big your project is, what chemicals you plan on using, and how much you are willing to spend. If you are uncertain of your next step and which fume hood you need, reach out to the staff at National Laboratory Sales and we’ll help you figure it out.