By definition, a fume hood is a ventilated enclosure that is designed to limit exposure to hazardous or toxic fumes, vapors, or dust.

As the most important appliance in a laboratory, fume hoods keep employees safe by removing harmful vapors and chemicals from the work area. The air they extract is then filtered by the building’s exhaust system before exiting the facility. That, right there, is the simple, two-sentence version of how a ducted fume hood works. But let’s dig a little deeper into how these devices function.

What is the purpose of a fume hood?

As stated, the primary purpose of the fume hood is to contain gases, vapors, and fumes and exhaust them out of the area. When used properly, fume hoods are one of the most reliable engineering controls in a laboratory. They protect users by:

-

- Containing vapors and fumes generated within the hood, and removing them from the laboratory through the exhaust system

- Shielding the user with a sash prevents injury from splashes, fires, or minor explosions that may occur inside the hood. Depending on its design, the sash may move vertically, horizontally, or a combination of the two

How does the fume hood work?

1. Pulls in contaminated air from the laboratory

The fume hood begins this process by pulling air from the room through the sash.

The air being pulled through the fume hood is measured in one of two ways:

- Volumetric Flow of Air: This is a measure of cubic feet per minute (CFM). This means that air is filling a cubic foot of space, and then the velocity at which air flows out of that space is measured. This is important because having too much or too little air will affect the performance of the hood. Finding the proper balance is what leads to optimal fume hood performance and efficiency. Because fume hoods move mass quantities of air, makeup air needs to be added to the room to maintain this proper balance.

If the room is small or if there are a large number of fume hoods in the same room, an additional supply of air may be required. If the makeup air supply is not adequate or the makeup air is switched off, then the fume hoods may not be able to achieve the required face velocity, which can cause fumes to escape into the laboratory.

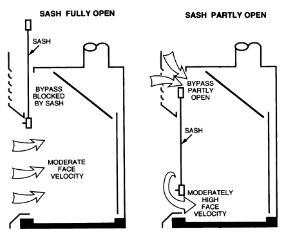

- Face Velocity: This is the speed of the air entering the front of the fume hood. The height of the sash plays a critical role in this measurement.

Think of face velocity as a garden hose that can’t quite reach the outer perimeter of the yard. Water will flow through a garden hose at a normal rate, but when you put your thumb on the end of the hose and create a partial blockade, the water exits with much more force. The same amount of water is still entering the hose and the same amount of water is exiting the hose. But because of the blockade of your thumb, the exit velocity increases. The same can be said for how air moves through a fume hood. The fume hood sash is acting as a blockade and can control the linear rate of air moving through the opening of the fume hood.

Types of fume hoods

- Constant air volume hoods: A constant air volume (CAV) fume hood exhausts the same amount of air all the time, regardless of sash position. As the sash is lowered and raised, the face velocity increases or decreases proportionally. Therefore, higher face velocities can be obtained by lowering the sash.

- Variable air volume hoods: A variable air volume (VAV) fume hood exhausts air flow based on sash height to maintain a set face velocity. As the sash is lowered and raised, the face velocity stays the same while less total air volume is exhausted.

VAV fume hoods are equipped with a monitor that indicates whether the hood is in “standard operation” or “standby operation” mode. The monitor also has an “emergency purge” button, which increases airflow through the hood and can be used to quickly remove contaminants from the lab. VAV fume hoods are equipped with flow sensors that activate an audible alarm when malfunctions occur.

2. Pushes vapors toward the exhaust area

As the airflow works its way through the middle of the fume hood, the hood pushes the harmful gases  and fumes toward the slots and baffles. The slots and baffles direct the air being exhausted toward the connected ductwork. In many hoods, the slots and baffles are adjusted to allow for even airflow. When used properly, baffles eliminate dead spots or reverse air flows which could result in vapors escaping the hood. If the baffles are closed or blocked by items inside the hood, the exhaust path will be blocked.

and fumes toward the slots and baffles. The slots and baffles direct the air being exhausted toward the connected ductwork. In many hoods, the slots and baffles are adjusted to allow for even airflow. When used properly, baffles eliminate dead spots or reverse air flows which could result in vapors escaping the hood. If the baffles are closed or blocked by items inside the hood, the exhaust path will be blocked.

3. Exhausts vapors through ductwork

An exhaust fan situated on the top of the building pulls the air through connected ductwork and releases it into the atmosphere. Or, in ductless fume hoods, the air is filtered and recirculated back into the room.

There are certain fume hoods for special uses and some even cater to specific chemicals. It is always best to consult the manufacturer’s recommendations for proper use and safety standards to ensure that your hood is efficient and effective.

National Laboratory Sales is the exclusive distributor of Fisher American fume hoods and also has a large selection of hoods from Labconco, Fisher Hamilton, Kewaunee, Hamilton Scientific, and many others. Search our impressive inventory to find a fume hood that works for you.